Keeping an industrial facility—be it a warehouse, factory, hospital, or school—clean and safe is a non-negotiable priority. While household mops are for light dust and spills, industrial mops are built for heavy-duty challenges: grease, chemical spills, heavy foot traffic, and vast floor areas.

Choosing the wrong mop can lead to inefficiency, safety hazards, and damaged floors. This guide will break down the main types of industrial mops and their key characteristics to help you make an informed decision.

1. The Loop Mop (Also known as a Knitted or Durable String Mop)

What it is: This is the classic industrial workhorse. It features a head made of continuous loops of yarn, typically made from robust materials like blended cotton, polyester, or poly-cotton.

- Characteristics:

- Highly Absorbent & Durable: The looped construction is less likely to unravel than a cut-end mop, making it extremely durable for rough concrete or textured floors. It can hold a large amount of water and cleaning solution.

- Excellent for Scrubbing: The thick, dense head provides significant scrubbing power to break up stubborn grime.

- Handles Heavy Soils: Ideal for grease, oil, and dirt commonly found in warehouses and manufacturing plants.

- Best For:

- Warehouses and factories

- Garages and auto shops

- Large, open areas with heavy soiling

2. The Cut-End Mop

What it is: Similar in shape to a loop mop, but the yarn strands are cut, creating a fringed appearance. This is often what people picture as a “traditional” string mop.

- Characteristics:

- Superior Scrubbing Action: The individual cut strands are more abrasive and provide a more aggressive scrubbing surface than loop mops, making them excellent for stripping wax or removing deeply embedded dirt.

- Good Absorbency: While very absorbent, they tend to wear out slightly faster than loop mops because the cut ends can fray.

- Softer Feel: Often made from softer cotton, which can be gentler on certain sealed floors (while still being aggressive).

- Best For:

- Floor stripping and waxing projects

- Sealed concrete or epoxy floors that need aggressive cleaning

- Facilities where scrubbing power is the top priority

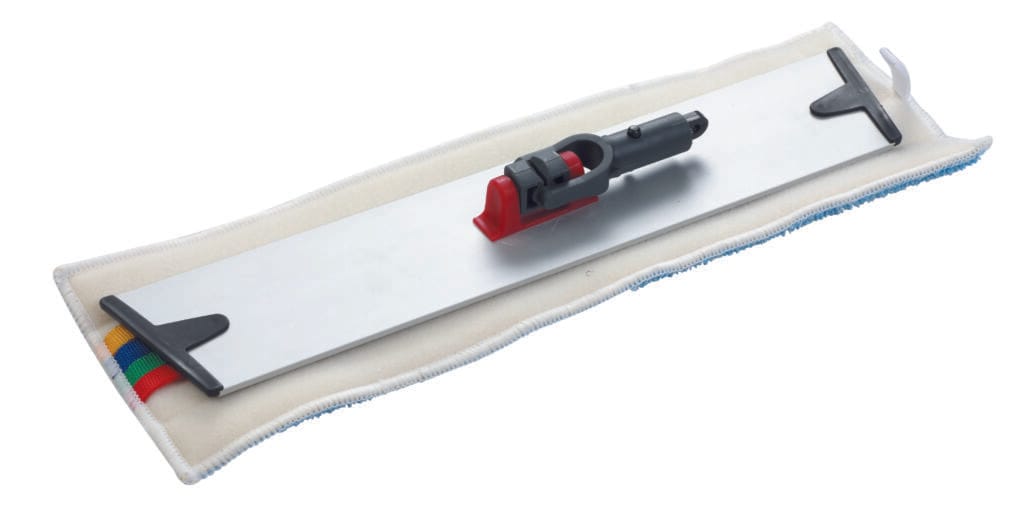

3. The Microfiber Flat Mop (Industrial Grade)

What it is: An industrial-strength version of the popular household flat mop. It features a large, sturdy frame that holds machine-washable microfiber pads.

- Characteristics:

- Highly Efficient Cleaning: Microfiber traps and removes up to 99% of bacteria and dirt from surfaces instead of pushing it around. This leads to a much cleaner result with less effort.

- Low Moisture: Ideal for “damp mopping,” which is safer for sensitive equipment and reduces slip hazards. It also dries quickly.

- Lightweight & Ergonomic: Reduces operator fatigue, making it perfect for large-area cleaning and daily maintenance.

- Cost-Effective in the Long Run: Reusable and washable pads reduce the ongoing cost of disposable materials.

- Best For:

- Hospitals, clinics, and cleanrooms

- Schools and offices

- Retail spaces and food processing areas (with color-coded systems)

- Daily maintenance cleaning on all floor types

4. The Deck/Broadcast Mop (Dust Mop)

What it is: A wide, flat mop designed for dry use. The head is typically made of yarn, treated yarn that attracts dust, or microfiber.

- Characteristics:

- Covers Large Areas Quickly: The wide head (often 24″ to 48″) allows a cleaner to cover vast floor spaces like aisles and hallways efficiently.

- Dry or Spray Cleaning: Used dry to collect dust, hair, and debris. It can also be lightly sprayed with a dust-control solution or disinfectant for damp dusting.

- Prevents Cross-Contamination: Using a dry mop first removes abrasive particles, preventing them from scratching the floor during wet mopping.

- Best For:

- Pre-sweeping large warehouses, gymnasiums, and showrooms

- Daily dust control in any large facility

- Preparing floors for wet mopping

5. The Strip Mop (Squeeze Mop)

What it is: A mop with a flat head, but instead of a microfiber pad, it uses strips of material (often cotton or synthetic) and features a built-in wringer, usually a roller style.

- Characteristics:

- Controlled Dampness: The roller wringer effectively squeezes out water, allowing for a perfectly damp mop ideal for applying finish or disinfectant without overwetting.

- Maneuverable: The flat profile allows it to get under low cabinets and equipment.

- Versatile: Good for both applying finishes and general cleaning.

- Best For:

- Applying floor sealants and finishes

- Hospitals and kitchens where controlled chemical application is needed

- Mid-sized areas that require precise moisture control

Key Considerations When Choosing an Industrial Mop

- Floor Type: Rough concrete can handle an aggressive cut-end mop, while a sealed epoxy floor might be better served by a loop or microfiber mop.

- Soil Type: Grease and oil require an absorbent, durable loop mop. Dust and bacteria are best handled by microfiber.

- Size of the Area: For massive spaces, a wide deck mop for dry work and a large-capacity loop mop for wet work are most efficient.

- Moisture Control: In areas where safety is critical, low-moisture options like microfiber or strip mops are essential to prevent slip-and-fall accidents.

- Ergonomics: Consider the weight of the mop when wet and the wringing mechanism to protect your staff from strain and fatigue.

Conclusion

There is no single “best” industrial mop. The right choice is a strategic one based on your specific facility’s needs. Many professional cleaning crews use a combination: a deck mop for daily dust removal, a microfiber mop for daily sanitization, and a heavy-duty loop mop for weekly deep cleaning or tackling major spills.

By investing in the right industrial mop, you invest in efficiency, safety, and the longevity of your facility’s floors.